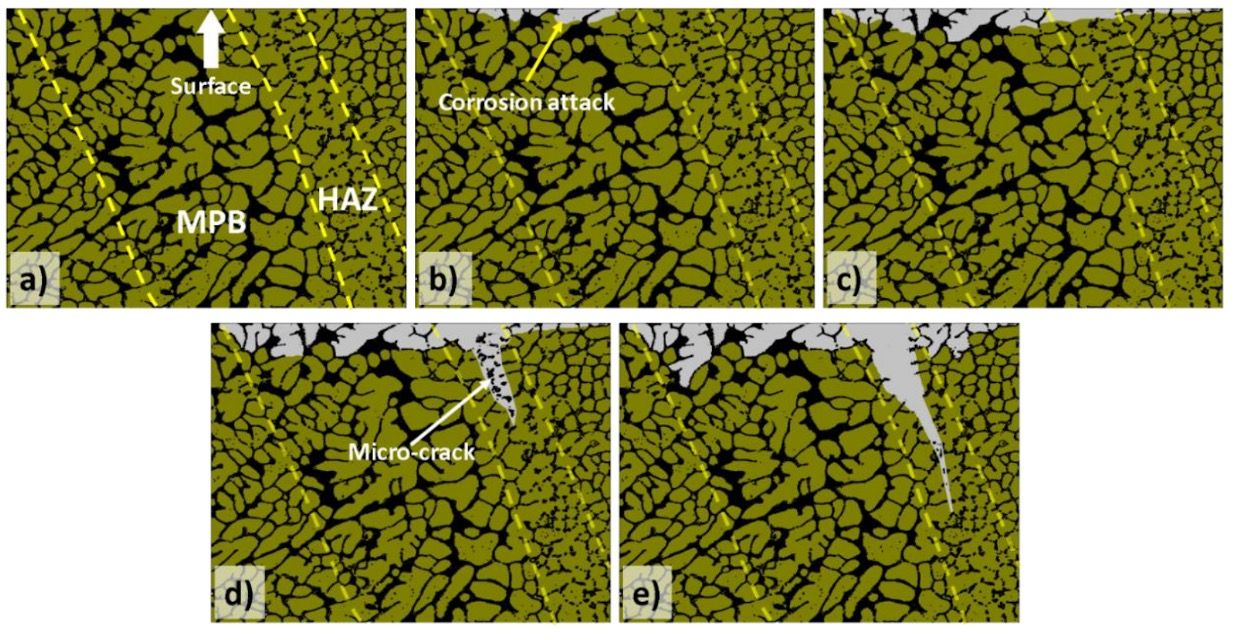

When the Additively Manufactured Aluminum is mentioned general reference was given to an Aluminum part created by Selective Laser Melting which is the most common practice for 3D printing of metals and it is the case for Aluminum. SLM Aluminum parts due to the nature of the method (See “Additively Manufactured Aluminum Without a Corrosion Compromise” for more information) contains specific micro sections in a melt pool referred as i) Core ii) Melt Pool Borders iii) Heat Affected Zone (HAZ) and there are several effects on said sections of microstructure for the corrosion behavior of the part. SLM Aluminum contains a cellular microstructure made of Silicon rich cell walls and an alpha aluminum core. In normal conditions the corrosive attack tends to propagate towards Alpha-Aluminum and after cleaning a single cell stops the process meaning said cell wall prevents further corrosion. But the borders of the melt pools have been identified as a significant aspect in the corrosion of these materials among the many characteristics of the microstructural features of Additively Manufactured Al-Si alloys. Several investigations have revealed that Al cells in the melt pool boundaries are selectively corroded during corrosion tests. Although it is thought to be a hard process penetrating the cell walls with corrosion, some researchers find that the melt pool borders inhabit large corrosion lengths and are a driving force to overcome cell borders' challenges.

Representation of corrosion attack in a SLM Al-Si alloy with different melt pool sections identified, MBP: Melt Pool Borders HAZ: Heat Affected Zone

The unique microstructure of additively built Al-Si alloys is the product of extraordinarily fast cooling rates and thermal gradient direction. The directional distribution of heat gradients during the fusion and solidification of the material's distinct layers results in an innately anisotropic microstructure. The microscopic alpha-Aluminum cells enclosed by the Si network are rounded in the plane parallel to the building platform, but elongated in the plane perpendicular to the building platform. Furthermore, elongated laser tracks are easily identifiable in surfaces parallel to the construction platform (XY plane), but a scale-like characteristic of melt pool boundaries is frequently visible in surfaces perpendicular to the building platform (XZ plane). It is currently controversial how this anisotropy affects the corrosion behavior. Even though there are some theories conflicting each other and not yet a useful analogy has been made.

In general, the literature for metallic materials demonstrates that the higher the surface roughness, the higher the corrosion rate. Copper, nickel, aluminum, stainless steel, magnesium, and titanium alloys all showed this pattern. The effect of producing varying roughnesses on both localized and overall corrosion performance of the alloys was examined in all circumstances. Looking at the situation with a wettability angle, wettability impacts corrosion rate, and generally speaking, larger water contact angles result in lower corrosion rates. The contact angle decreases as the volume fraction of primary Si rises in Al-Si alloys between 7 and 50 percent. For samples roughened with 240 or 800 grit sandpaper, the water contact angle reduces from almost 80° to 65° as the weight percentage of silicon rises from 7% to 50% for the same degree of roughness and droplet size. It is also observed that an increasing contact angle is occurring with increasing surface roughness for Al-Si alloys.

Despite the fact that several studies have shown that the special conditions during 3D printing of Aluminum have a significant impact on the microstructure and corrosion behavior of these materials, few studies have been dedicated to investigating the impact of their special microstructure on corrosion protection mechanisms. These studies have been conducted so far to investigate the effect of microstructure, heat treatments, Si content, and flaws on the anodizing behavior of Al-Si alloys produced by selective laser melting. This anodization process of Aluminum and aluminum alloys is conducted to increase the corrosion resistance of the part. There has not yet been a successful and consistent application of anodization made for SLM parts made with Al-Si alloy. Studies concluded that SLM-produced Al-Si alloys can be anodized. It was demonstrated, however, that the distinctive microstructure of SLM manufactured components has a considerable influence on the voltage-time response and the developed anodic oxide film. Furthermore, when compared to a cast alloy of the same chemical makeup, they demonstrated dramatically different anodizing behavior. The voltage-time response of the cast alloy exhibits the normal steady-state growth regime, but the AM material exhibits a continuous increase in voltage until a steady-state is attained. The moving oxide front will be hindered to a greater extent in additively manufactured Al-Si alloys due to the fine distribution and strong connectivity of the Si network, resulting in the production of a thinner oxide layer. Furthermore, the SLM alloy had a considerably lower oxide development rate than the cast alloy. This reduced oxide growth rate was attributable to Si oxidation consuming a greater percentage of the anodic charge in the SLM alloy. Furthermore, significant anisotropy was observed during galvanostatic anodizing of additively manufactured Al-Si samples. The voltage-time response curves of the anodized surface exhibited a varied response with different orientations. The voltage-time response of a surface parallel to the building platform (XY surface) is considered to have a larger steady-state potential value than a surface perpendicular to the building platform (XZ surface). This asymmetric anodizing behavior is independent of the alloy's Si concentration. The reason for said asymmetry is thought to be caused by differences in the size of aluminum cells on various planes, or simply by the density of melt pool boundaries encountered by the anodizing front.

With current studies showing a complicated process for complicated new microstructures inside the additively manufactured aluminum parts, currently, the industry does not have a reliable corrosion protection service available thus having to ship parts without any protection, so a compromise is made in the sector. But with the emerging technologies and recent developments in computer science, this problem can be solved. The Anodization of said additively manufactured parts is possible and can also be economically viable with the help of automated systems powered by an Artificial Intelligence network improving the parameter and solving the complicated adjustment problems encountered in the anodization process. Currently, in iyiMetal this solution is proven to be successful and shows a greater future promise for the industries using Al-Si alloys such as automotive, aviation, and aerospace. Especially in the automotive industry considering the emergence of the E.V market and with the pressure of Green Deal, Aluminum parts used in the sector are higher than ever and this anodization problem should be solved to design, manufacture and create parts that do not compromise on quality.

References

1-Martin, John H., et al. "3D printing of high-strength aluminium alloys." Nature 549.7672 (2017): 365-369.

2-Blakey-Milner, Byron, et al. "Metal additive manufacturing in aerospace: A review." Materials & Design 209 (2021): 110008.

3-Shakil, S. I., et al. "Additive manufactured versus cast AlSi10Mg alloy: Microstructure and micromechanics." Results in Materials 10 (2021): 100178.

4-Verkens, D. "Study of the anodizing behaviour of additive manufactured AlSi10Mg aluminium alloy." Vrije Universiteit Brussel (2016): 2017-10.