Additive Manufacturing (A.M) also known as 3D Printing has been one of the main focus of production techniques in many industries in the 21st century due to its high promise in various areas creating a multi-billion USD industry both in production and research & development. With the push of the sector and the ever-increasing interest of the industry, metal additive manufacturing technologies are increasing at a fast rate to fill the needs of many with the un-parallel capabilities that are not possible to fulfill with any other metal production method. The rapid pace of the worldwide development of this technology and its adaptation of commercially-availability is quite prominent.

The main principle of additive manufacturing is to create a part with the layer-by-layer approach. Creating a new layer on top of the existing one with a precise technique. Because of this layered nature, it is also referred to as Layered Manufacturing. This type of approach is significantly beneficial for creating complex structures which are much harder to produce using traditional methods. Although there are several types of achieving said Layered Manufacturing existing under the additive manufacturing roof, Selective Laser Melting (SLM) accounts for most of the industry with its on-point accuracy, melting a loose powder bed with high precision laser creating layers after layers.

The last decade shows highly promising improvement in the metal additive manufacturing market and it is valid to assume this increase in the market is a direct result of the increase and availability in the technology.

Considering the ongoing research efforts still in progress and the ever-reaching new goals in the quality side of the parts, it is not irrational to assume this increase in the market is not going to slow down any time soon.

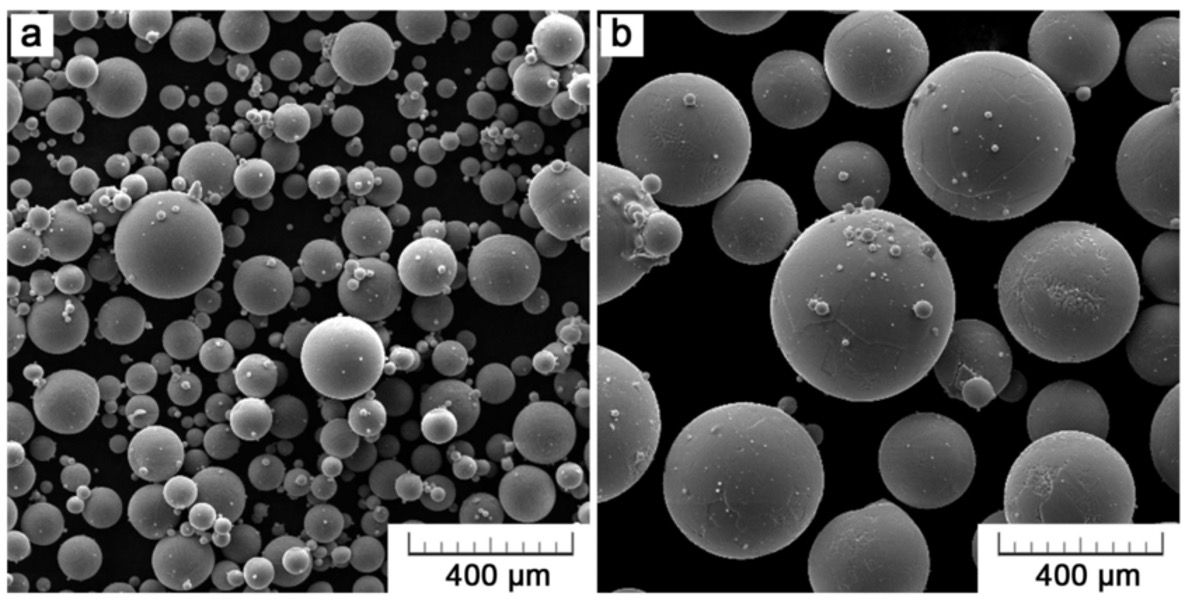

The basic concept behind A.M - SLM production is boiled down into two main acts; deposition of the prepared metal in a powder form and scanning of the designated cross-sectional area with a high-energy laser to achieve precision local melting in the desired spots. Both of these processes involve delicate engineering for obtaining optimum performance. The powder is the building block of the process and the selection of the right powder is crucial. This selection and preparation are done according to the particle size, surface finish, and microstructural composition. It is also important to utilize optimum moisture and oxide levels which can affect the final property of the material.

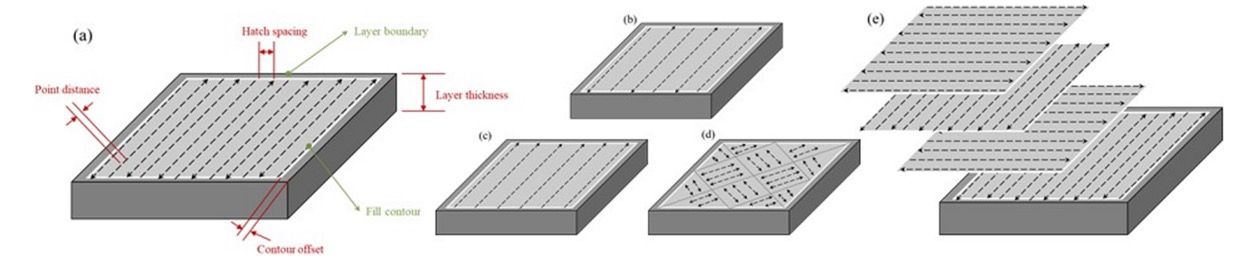

The Scanning process of SLM can be divided into three parts starting with a single dimensional line, a scan track, created with said mechanism, a horizontal overlap of multiple scans tracks creating a layer, and the vertical overlap of the layers completing the 3D structure. Throughout this process important parameters fall under four distinct categories;

Laser Related: Laser Power, Laser Size, Pulse Duration, Pulse Frequency

Scan Related: Scan Speed, Scan Spacing, Scan Pattern

Powder Related: Particle Size, Particle Shape and Distribution, Powder Bed Density, Layer Thickness, Material Properties.

Temperature Related: Powder bed temperature, Powder Feeder Temperature, Temperature uniformity.

Materials that have high-reflective properties such as Aluminum consequently require higher power lasers in order to melt without a problem. Otherwise, the partial melting of the spot could lead to a distortion of the alloy.

With this many variables to account for in such a young technology, the constant improvement and optimization of the process are well expected and every new achievement consequently means high promise for the future of the technology.

Selecting an alloy suitable for the SLM production is considered to be similar to the alloy selection in the casting process and welding process. Although there are some similarities across the methods the difference is still quite significant. The most important and also the most unique difference in terms of SLM is the very high cooling rates subjected to the alloy that might cause all sorts of problems that need to be overcomed by selection of the right alloys.

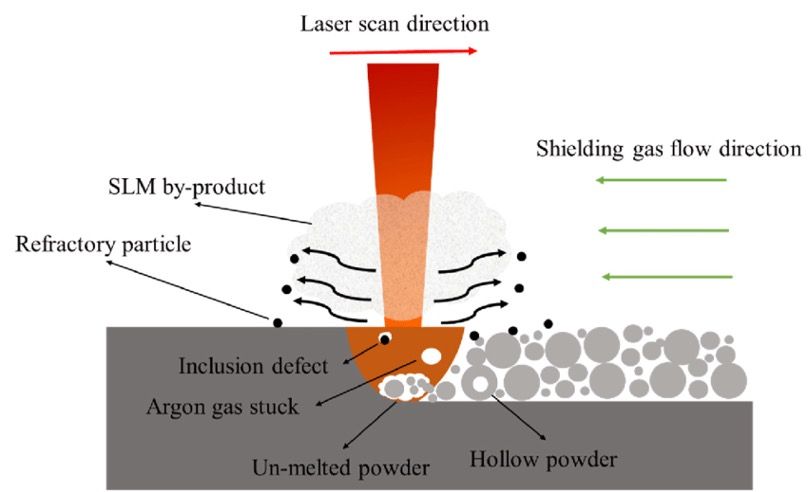

Investigating a part produced with SLM with two main perspectives:

Structural Integrity: Resultant parts inherit

-High residual stress

-pores

-cracks

-inclusions resulted from laser spatter

-surface irregularities

Metallurgically: Resultant parts inherit

-Fine Microstructure

-Anisotropic mechanical behaviors

In terms of Additive manufacturing of Aluminum with SLM process overcoming said challenges with conventional 2xxx,5xxx,6xxx, and 7xxx alloys is not fully doable with industrial scales, and high cooling rates in SLM result in these alloys micro-crack resulting in parts that are unusable in terms of structural integrity. They simply aren’t considered successfully processable by SLM. But the unique properties observed in the Al-Si alloys exhibit advantageous ease in the production of 3D Printed Aluminum.

It is observed that with increasing Silicon content the viscosity of the molten metal decreases. Looking at the phase diagram of the Al-Si, increasing silicon content results in a lower melting temperature up until the eutectic point. This decrease in melting temperature providing a lower viscosity works very well in favor of the previously explained SLM mechanisms. One of the main reasons for encountering a malfunctioning product is that there is not enough time for the molten metal to fully encapsulate the melting pools resulting in defects leading to problems in the Structural integrity side of things.

But creating a low viscosity alloy with the help of added silicon provides a perfect fit for avoiding such problems because with the lack of resistance to flow (definition of low viscosity) the molten metal is enabled to move much quicker than other alloys and this provides plenty of time to encapsulate the melting pools properly avoiding the unwanted defects.

These benefits result in AlSi10Mg and AlSi12 alloys gaining the most attention with additive manufacturing of the Aluminum parts. The work and research being done for these Al-Si alloys massively surpass the other aluminum alloys.

To further increase the properties of SLM Aluminum alloys it is also necessary to provide a high temperature in the melt pools working towards further lowering the viscosity level.

These 3D printed Al-Si alloys are one of the main focuses in many industries such as automotive, aerospace, and aviation specifically with the parts that demand complex structural design.

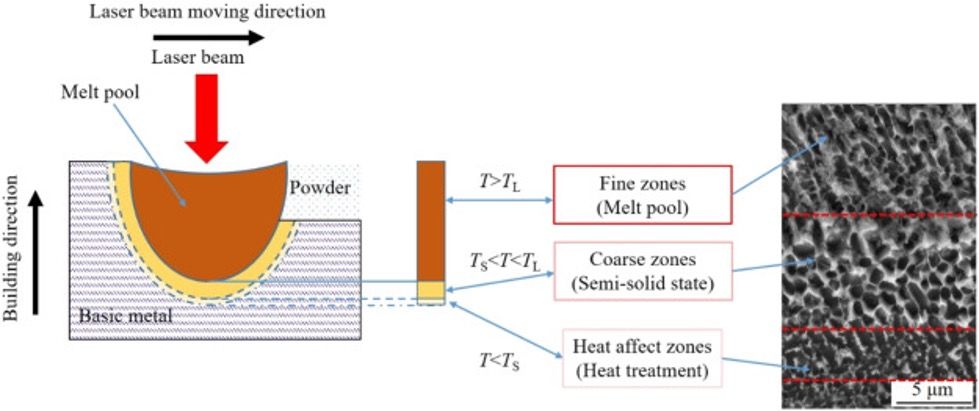

Investigating the microstructural properties of the Al-Si alloy parts manufactured with the SLM process the solidification mechanism is observed as cellular-dendritic, to identify more broadly one should consider the proposition that the history of heat equals the microstructure. During the SLM process, the material is put through to thermal gradients that are very high and re-melted repeatedly due to both the penetrating power of the laser beam across the layers and the overlaps in the scan track. Cooling and solidification happen very rapidly, between 10^3 to 10^8 Kelvin per second, resulting in a fine microstructure made by metastable phases. This fine microstructure is opposite to the coarse microstructure observed in traditional casting

With a first glance three distinct sections of each melt pool manifests themselves as important in terms of temperature:

i) Core of the Melt pool providing a cellular pattern in a finer equiaxed structure. Referred to as “Fine Zones”.

ii) Melt pool boundary providing coarser cells that are elongated. Referred to as “Coarse Zones”.

iii) Heat-affected Zones.

Each section provides different properties and the amounts and locations of said sections are determined by various parameters such as the partial overlap ratios in the scan track creating re-melts and cooling rates subjected to the aluminum powder. Various combinations give a very wide range of properties in the final product allowing the possibility of tailoring in the production.

Aluminum in its natural form has a tendency to become corrosion resistant due to its nano-scale oxide layer formed on the surface. To further increase this beneficial property an electrolytic passivation process, anodizing is used for creating an even thicker oxide layer increasing the scale from nano to micro level.

Although it is quite a common and simple process to anodize some aluminum alloys, working with high silicon aluminum alloys which has a large place in additive manufacturing and casting part industries it is still not conveniently anodized for commercial use. Even though the addition of silicon into the metal allows it to become much more processable in terms of casting and additive manufacturing, the presence of silicon interferes with the anodizing process which eliminates a standard practice in traditional aluminum part production. An algorithm-based method created specifically to supervise the anodizing process of high silicon aluminum alloys is currently being developed in iyiMetal to overcome the shortcomings and allow the mass production of the said high silicon Aluminum alloy anodizing process. Creating this process on an industrial scale would enable a broad new range of possibilities in many industries such as Automotive, Aviation, and Aerospace that heavily use this type of high silicon aluminum alloy parts in their design. With the recent developments in artificial intelligence over the last decade, implementing this newly developed technique into coating technology is the basis of the process.

The said anodizing process is a life-extending coating mechanism aiming to increase the quality of the part for better performance. The absence of this vital coating process in the parts produces with additive manufacturing or SLM, implicates some serious performance deficiencies mostly in terms of quality of life and longevity of the part. Being able to anodize previously mentioned parts would create a path to a longer life, hustle-free user experience.

References

1-Verkens, D. "Study of the anodizing behaviour of additive manufactured AlSi10Mg aluminium alloy." Vrije Universiteit Brussel (2016): 2017-10.

2-Blakey-Milner, Byron, et al. "Metal additive manufacturing in aerospace: A review." Materials & Design 209 (2021): 110008.

3-Aboulkhair, Nesma T., et al. "3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting." Progress in materials science 106 (2019): 100578.